ENCY: CAD/CAM

for a new generation

Delivering sophisticated CAM technology with an intuitive user interface and natural workflow

|  |  |  |  |

|---|

ENCY - CAD/CAM for 2.5D and 3D millinging

Roughing Waterline

Roughing Waterline in ENCY offers adaptive and equidistant roughing strategies to ensure optimal material removal for complex parts, automatically selecting the best approach based on the geometry.

Adaptive and Equidistant Strategies:

The system intelligently applies adaptive or equidistant roughing strategies, depending on the specific features of the part, ensuring efficient material removal and constant tool engagement.

Automated Strategy Selection for Diverse Geometries:

Automatically selects the optimal approach for various part features such as closed and open pockets, wells, grooves, bosses, ribs, and slots, covering all key elements typically encountered in roughing operations.

Stock-Aware Toolpath Calculation:

Continuously updates the state of the stock material, generating efficient toolpaths that minimize air cutting and maximize material removal.

Super-Fast Toolpath Calculation:

ENCY’s advanced algorithms provide ultra-fast toolpath generation, significantly reducing the time needed to prepare roughing operations and accelerating overall production.

Adaptive Feedrate:

Dynamically adjusts the feed rate based on cutting conditions, ensuring optimal tool load. It enhances efficiency by accelerating in lighter material zones and slowing down in tougher areas, improving both machining time and tool lifespan.

ENCY Rotary: 4-axis CAD/CAM

|  |  |

|---|---|---|

|

Roughing Waterline

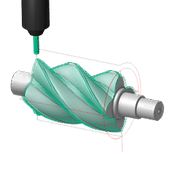

Rotary Roughing

The rotary roughing strategy is optimized for removing large volumes of material in rotary machining operations. It generates robust toolpaths that follow the rotary axis, ensuring effective material removal while preserving stability. This strategy is particularly suited for initial machining stages, where the focus is on shaping the workpiece quickly and efficiently.

Equidistant Strategy

The equidistant roughing strategy ensures uniform material removal by maintaining a constant distance between toolpaths. This delivers consistent cutting conditions, reducing stress on the tool and the machine while creating a balanced roughing process. It’s ideal for achieving predictable results and setting up a smooth transition to finishing.

Adaptive Strategy

The adaptive roughing strategy dynamically adjusts the toolpath to maintain optimal cutting engagement, minimizing air cuts and reducing tool wear. This approach enables high-speed rotary machining with greater efficiency, allowing for rapid material removal while maintaining precision and control.

These advanced roughing strategies in ENCY provide comprehensive solutions for rotary machining, enabling users to handle diverse machining requirements with precision and efficiency.

ENCY: CAD/CAM for 5-axis machining

|  |  |

|---|---|---|

|  |

5-axis machining with ENCY

True Machine-Aware Programming

Toolpaths are generated with full awareness of the machine’s kinematics, limitations, and specific configurations. This ensures collision-free motion, optimal cutting conditions, and maximum utilization of the machine’s capabilities.

Supported Kinematics

Supports a wide range of kinematic configurations, including head-head, table-table, and head-table setups. The system adapts to each machine’s unique structure, allowing for accurate and efficient 5-axis machining.

TCPM, RTCP, TPW Support

With Tool Center Point Management (TCPM), Rotary Tool Center Point (RTCP) support and Tilted Working Plane with LCS (TWP), tool orientation adjustments are seamless, minimizing tool deflection and improving surface finish quality.

Check Holder

Real-time holder collision detection ensures that the tool assembly clears all workpiece and fixture obstructions, preventing potential crashes.

C-Axis Singularity Avoidance

Intelligent toolpath planning mitigates C-axis singularities, ensuring stable motion and preventing erratic tool behavior during machining.

ENCY for swiss lathes programming

|  |  |

|---|---|---|

|

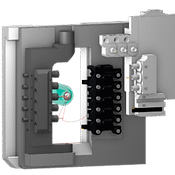

ENCY for Swiss-type machines in action

Applications

2.5x and 3x mill

production of mold and dies and any other part of 3 axis machine

Multiaxis

index (3+2) and simultaneous

5 axis milling for

turbine ,blade, ports

Rotary

Production of screw,

blades ,gear wheels,

baluster

Lathe

Turning and boring, threading, trimming, drilling, reaming

Mill-turn

Turning and milling combined in one setu

HSM and adaptive

High speed and

adaptive toolpaths for quick material removal with extended tool life

Swiss ans MTM

Swiss-type machine

and MTM with synchronization

5-6D cutting

CNC programming of cutting, trimming, 6D knife cutting. Mill, laser, water, plasma, knife

Additive

in3D -5D Cladding

with advance layer

thickness

EDM

2 – 4 axis strategies

for wire EDM

machining

2D cutting

Programming of laser, waterjet, plasma, oxy-fuel cutting and knife cutting

G-code based simulation

G-code verification in ENCY CAM

Probing cycles

Probing cycles for Milling and Lathe Machines

ENCY: CAD/CAM for a new

generation

Delivering sophisticated CAM technology with an intuitive user interface and natural workflow

State-of-UI

3-aixs toolpath

HSM

Machine simulation

Multiaxis

Additive

material removal

simulation

Collaboration

Mill-turn

.png)

A wide range of machining strategies from 2D to 5D

Parametric CAD

interactive

NC-code simulation and verification

A State-of-art interface

Crisp at 4K screens

Open API

Technological independence

Why Ency Cam

Ency Certified Gold Product

Certified Gold Products are best-in-class, third-party software solutions designed specifically for SOLIDWORKS. A SOLIDWORKS committee ensures that these products can effectively perform the designated tasks and have the necessary resources to keep the solution synchronized when changes occur to the SOLIDWORKS data. Certified Gold Products offer seamless integration, allowing all operations to take place within the SOLIDWORKS interface, and adhere to a comprehensive set of user interface guidelines to ensure a familiar and intuitive experience for users.